I’ve been working on a mount for a Carplay Screen for my car I purchased on Amazon. I have done prints for my car before, and heat has been a challenge especially with PLA plastic. I usually print things in PLA (and I have a decent supply of it.)

Going into this - I fully expected the first prototype to warp, especially since it’s black colored and sitting in a hot car can quickly make the PLA decently malleable. I plan to reprint this all in ABS plastic to enhance its heat resistance once I have the design finalized. I figure, If I can get it to at least sort of survive the summer heat, when it’s reprinted, it will be much more durable.

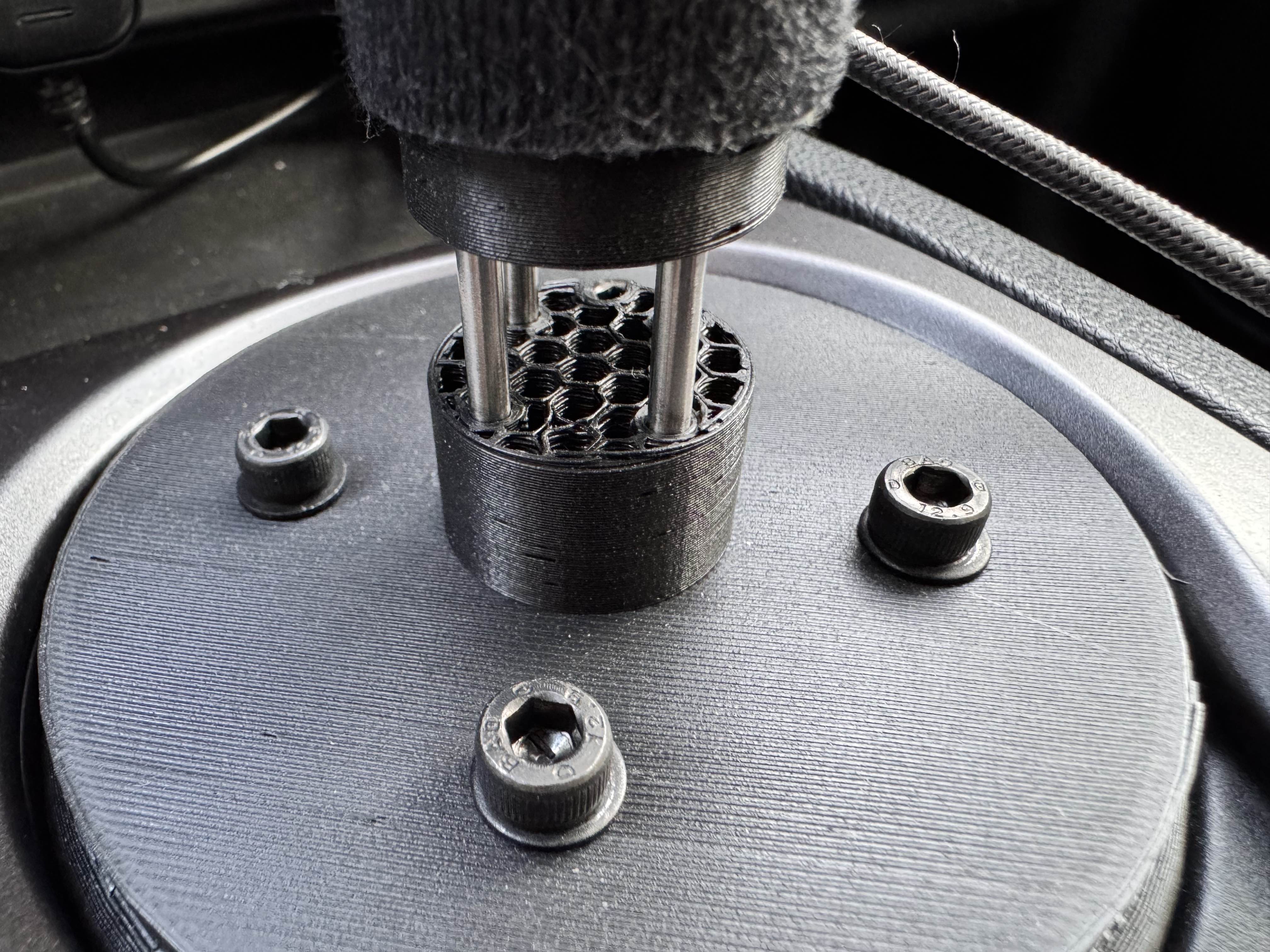

Part of this design to help combat any warping, even with having ABS - is the 4 stainless steel rods run throughout the entire vertical structure of the print.

Once I finalize the design, I’ll share it here.

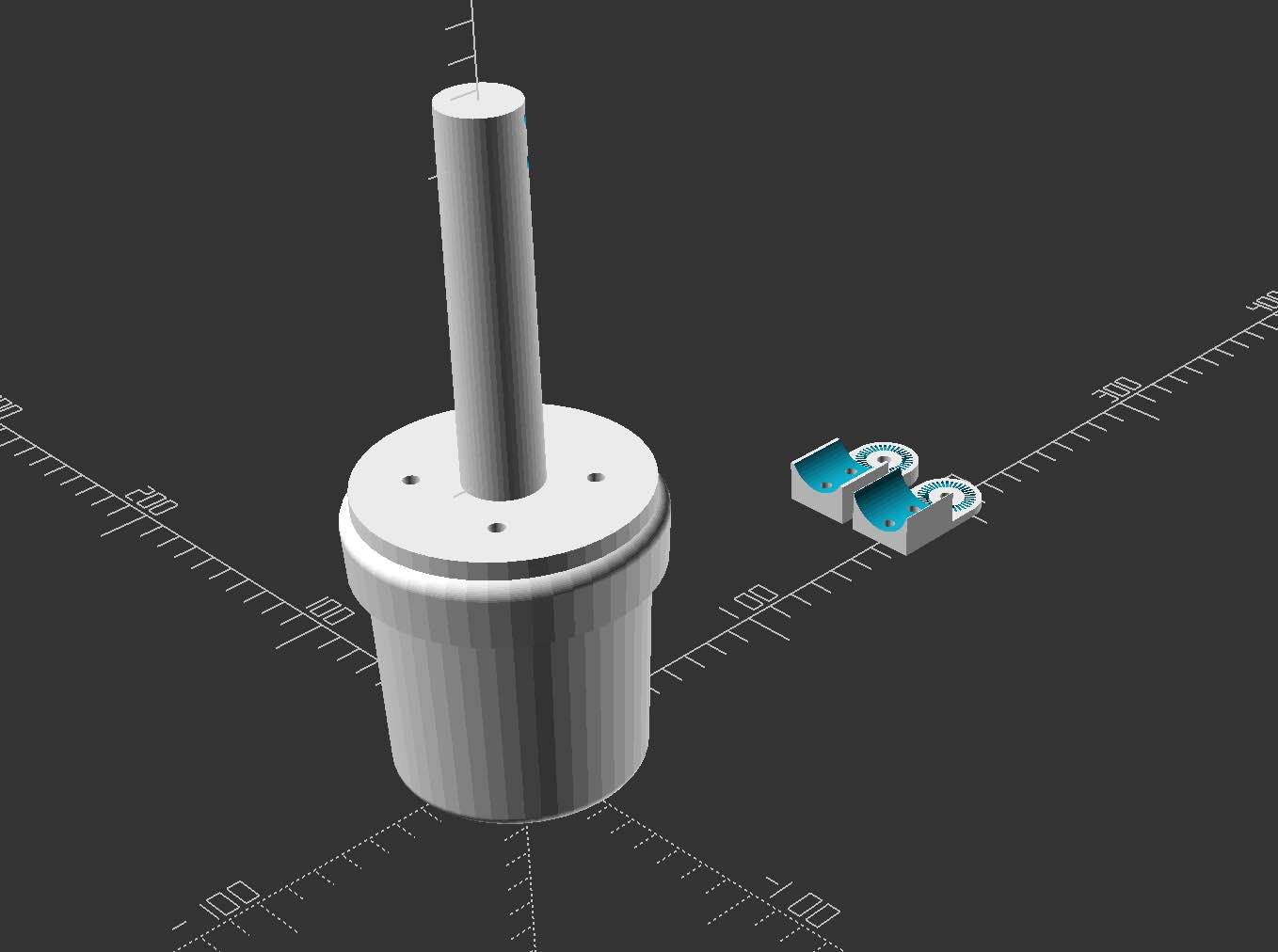

Overall Design

This will consist of the following parts

- Printed Cupholder Base - modular, so I can design other cupholder mounts for other cars

- Pillar

- 4x Stainless rods - for strength

- Top brackets - to allow using the mount provided with the screen

- Hardware - Assorted m4 / m5 hardware, and bolt/thumbscrew provided with the screen

- M5x10 Heat inserts - 4x

Modeling the Cupholder

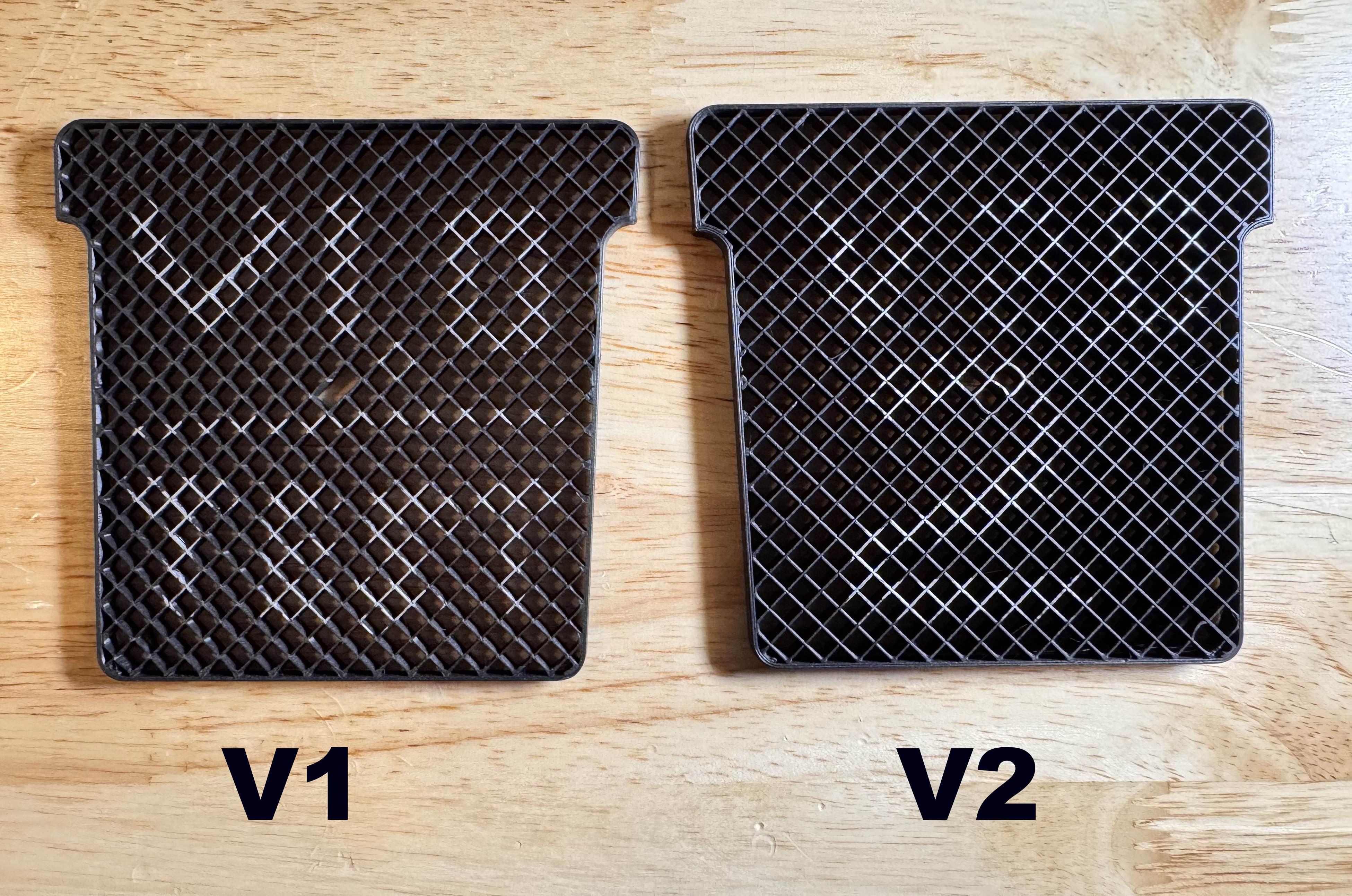

First, I modeled the cupholder - the first print ended up to fit quite nicely, but I adjusted it slightly in a re-print.

Support Rods

Due to a convenient printing mishap, the pillar split near the bottom, it shows how the stainless rods providing support for the screen:

Version 1

This is the first version, mounted in the car:

Warping Test Results

Owing to the support rods, most of the print survived a few days in the summer heat. Except (as I expected), the top. Based on this, I redesigned one side that could be thickened to be twice the thickness, and printed at 90% infill.

Reprinting With ABS

This worked very well. I only needed to reprint the top brackets, and it withstands the sun pretty well and isn’t warping thanks to the metal supports.

The only thing I’m noticing over time, is that the base is slightly looser than it was when I originally printed it. I’m assuming this is due to temperature.

This post is a work in progress, and may be updated at some point in the potentially distant future!

This post is a work in progress, and may be updated at some point in the potentially distant future!